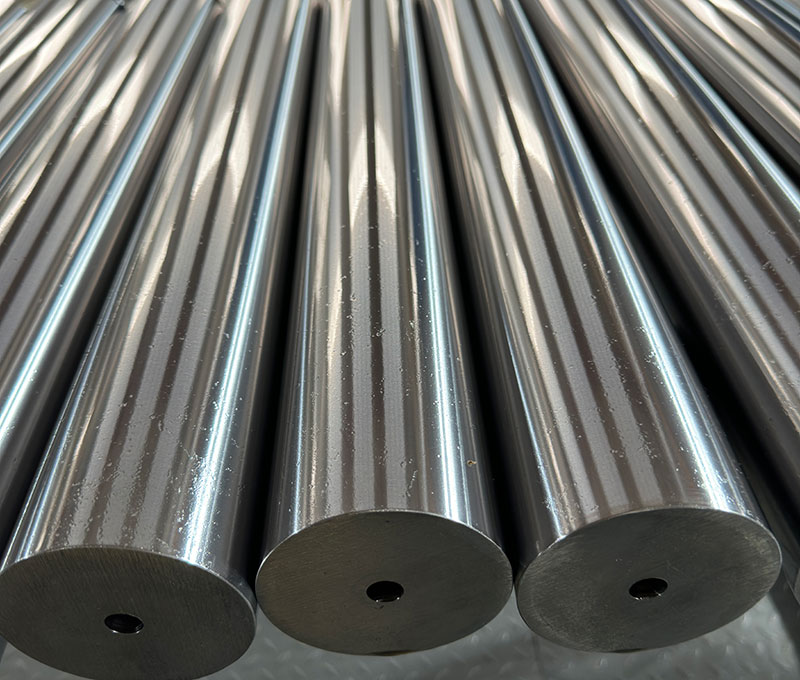

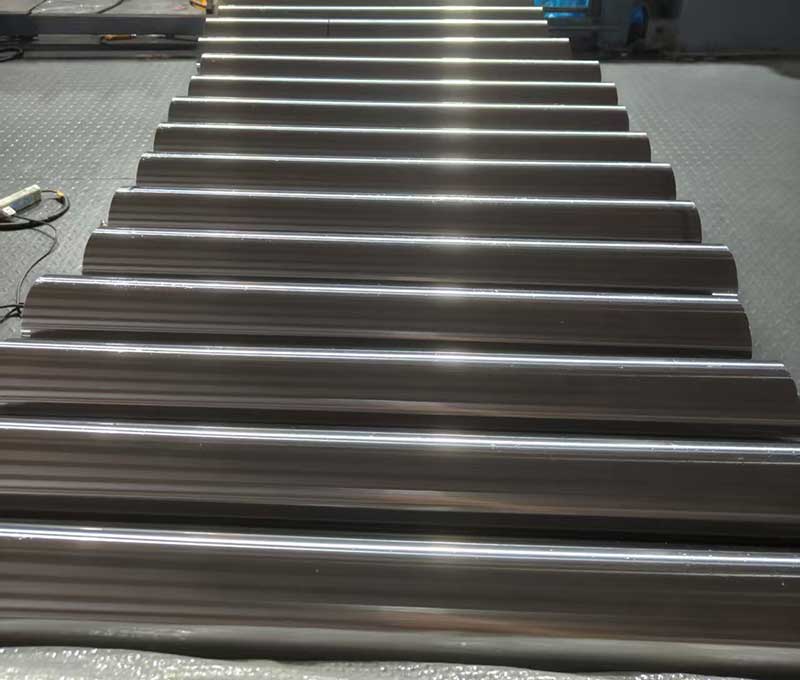

20MnV6 Chrome Plated Rods

20MnV6 Chrome Plated rods

Material: 20MnV6

Length: Max 18m

Shape: Round bar

Roughness: Ra <= 0.2u

OD Diameter: From 6mm to 800mm

Diameter tolerance:ISO f7/h8/g6

Heat treatment: Hard Chrome Piston Rod ( HRC 15-20)

Quenched & Tempered (Q+T) Rod (HRC 28-32)

Induction Hardened Rod (HRC 55-62)

Q+T Induction Hardened Rod (HRC 60-65)

Chrome thickness: As per request 20 to 100 micron

Protection:anti-rust oil on inside and outside surface, plastic caps in both ends.

20MnV6 Chrome Plated Rods Chemical Composition and Mechanical Properties

20MnV6 Chrome Plated Rods Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.17 – 0.24 |

| Silicon (Si) | 0.17 – 0.37 |

| Manganese (Mn) | 1.30 – 1.60 |

| Phosphorus (P) | ≤0.035 (allowable residual content) |

| Sulfur (S) | ≤0.035 (allowable residual content) |

| Chromium (Cr) | ≤0.30 (allowable residual content) |

| Nickel (Ni) | ≤0.30 (allowable residual content) |

| Copper (Cu) | ≤0.30 (allowable residual content) |

| Vanadium (V) | 0.07 – 0.12 |

20MnV6 Chrome Plated Rods Mechanical Properties

- Tensile Strength (σb): ≥785 MPa (80 kgf/mm²)

- Yield Strength (σs): ≥590 MPa (60 kgf/mm²)

- Elongation (δ5): ≥10%

- Reduction of Area (ψ): ≥40%

- Impact Energy (Akv): ≥55 J

- Impact Toughness Value (αkv): ≥69 J/cm² (7 kgf·m/cm²)

- Hardness: ≤187 HB (annealed or high – temperature tempered condition)

20MnV6 Chrome Plated Rods Physical Properties

- Density: Approximately 7.85 g/cm³

- Thermal Conductivity: Around 49 W/(m·K) at room temperature

- Specific Heat Capacity: Approximately 0.49 J/(g·K)

- Melting Point: Typically 1425 – 1540 °C (2600 – 2800 °F)

- Magnetic Properties: Typically ferromagnetic

20MnV6 Chrome Plated Rods Primary Alternative Materials

A. 4140 (AISI/SAE)

- Chemical Similarity: Contains chromium and molybdenum instead of vanadium, enhancing hardenability and resistance to wear.

- C: 0.38–0.43%

- Cr: 0.80–1.10%

- Mo: 0.15–0.25%

- Mechanical Match: Offers higher tensile strength (≥1030 MPa) and comparable toughness, making it suitable for heavy-duty components like axles and gears.

- Application Fit: Ideal for parts requiring extreme durability but can be costlier and less weldable than 20MnV6.

B. 20CrMo4 (EN 10083)

- Alloying Elements: Combines chromium and molybdenum, similar to 4140 but with lower carbon content (0.17–0.23%).

- Advantages: Excellent case hardening properties and good corrosion resistance, suitable for components like camshafts and connecting rods.

- Trade-off: Slightly lower strength than 20MnV6 but superior machinability and weldability.

C. 1045 (AISI/SAE)

- Carbon Steel Alternative: A non-alloyed medium-carbon steel with 0.42–0.50% carbon.

- Benefits: Lower cost and easier availability, suitable for less critical applications like general-purpose shafts or bolts.

- Limitations: Lower hardenability and strength compared to 20MnV6; requires heat treatment to match performance.

D. 20MnB4 (EN 10084)

- Vanadium Substitute: Uses boron to improve hardenability, with similar carbon and manganese levels to 20MnV6.

- Application: Commonly used in automotive components (e.g., gears, bolts) where cost-effective high strength is needed.

20MnV6 Chrome Plated Bars' Application & packing & Transportation

20MnV6 Chrome Plated Rods Applications

It is widely used in manufacturing various mechanical parts, such as automotive steering knuckles, rear axles, machine-tool gears, shafts, worms, spline shafts, and bushings. It is also suitable for making welded structural parts like boilers, high pressure vessels, and large diameter high pressure pipes. In addition, it can be used for cold drawn and cold stamped parts such as piston pins and gears.

20MnV6 Chrome Plated Rods Packaging and Transportation

- Packaging: Usually packed in woven bags, wooden boxes, or loaded into 20 foot or 40 foot containers for standard seaworthy packaging.

- Transportation: Can be transported by sea, air, or land logistics.

Delivery Time

- Usually 7 – 15 days after receiving the deposit, but it may vary depending on the order quantity and production schedule.