304 Chrome Plated Stainless Steel Bar

304 Chrome Plated Stainless Steel Bar

304 Chrome Plated Stainless Steel Bar Application :

• Pneumatic / Hydraulic Cylinder Shaft

• Textile Components

• Pump Shafts & Rotors

• Fitness Equipment

• Automobile & Mechanical Components

• Plastic & Rubber Rolls, Moulds, Dies, Screws etc

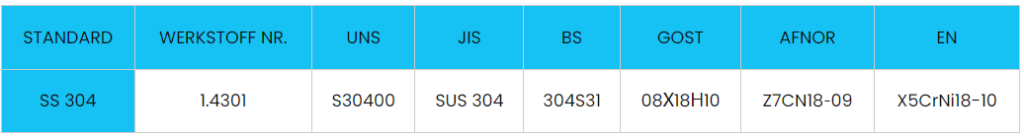

Material Grade:SS304/SS304L/1.4301/1.4307/UNS S30400/SUS304/304S31/X5CrNi18-10/27CN18-09

Size Range : 12 MM To 800 MM (Above 800 MM can be made as per customer design & specification)

Maximum Length : Up to 7500 MM or as request

Hard Chrome Plating Thickness : min.25 To 30 Microns(As per request)

Surface Finish : RA0.1µm – RA0.4 µm

Chrome Surface Hardness : 850 to 1000HV

Straightness : 0.1 per meter max.

Products List

SS316/316L Hard Chrome Plated Bars

316L Stainless Steel Hardened Hard Chrome Plated Shaft

420 Induction Hardened Hard Chrome Rod

410 Chrome Plated Shaft

304 Stainless Steel Chrome Bar

316 Stainless Steel Chrome Plated Bar

304 Stainless Cold Rolled Rod

S30400 Stainless Chrome Plated Bar

1.4301 Stainless Steel Round Bar

X5CrNi18-10 Stainless Steel Round Rod

SUS304 Stainless Cold Rolled Bar

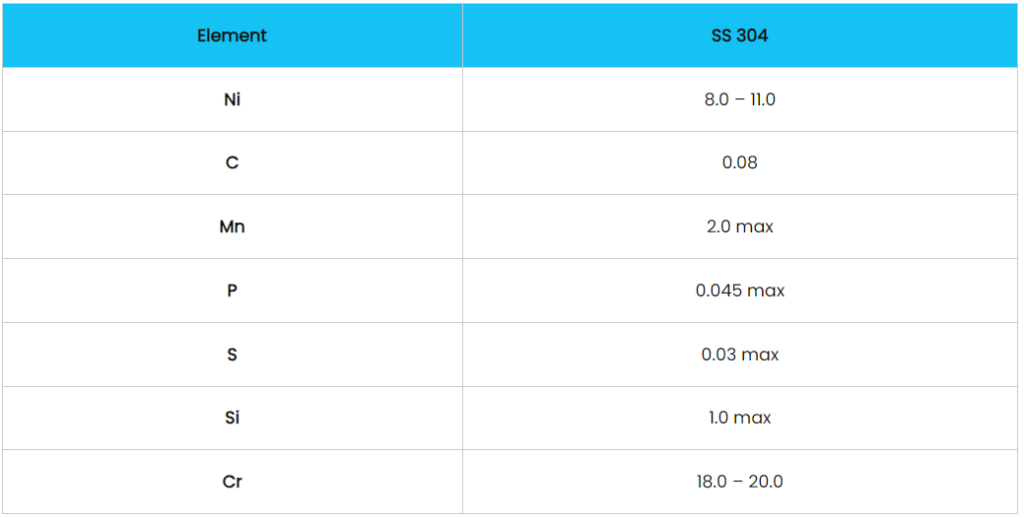

304 Chrome Plated Stainless Steel Bar Round Bar Chemical Composition

304 Chrome Plated Stainless Steel Bar round bar Equivalent Grades

304 Chrome Plated Stainless Steel Bar are typically manufactured using one of two processes: hot rolling or cold drawing.

Hot rolling involves heating the stainless steel billet to a temperature above its recrystallization temperature and then rolling it into a round shape. The resulting bar is then cooled and cut to the desired length.

Cold drawing, on the other hand, involves pulling the stainless steel through a series of dies to create the desired shape and size.

304 Chrome Plated Stainless Steel Bar/304 Stainless Steel Round Bar is austenitic steel with non-magnetic features in the annealed form that offers excellent corrosion resistance to both atmospheric and chemical exposures, in the company of elevated resistance to oxidation.

304 Stainless Steel Round Bar (SS 304 Rods) has excellent forming and welding features. To the national and international quality of raw materials, we also offer these UNS S30400 Round Bars (also known as WNR 1.4301 Bars) in customized sizes and thicknesses per our esteemed clients’ specific demands at market-leading prices.

304 Chrome Plated Stainless Steel Bar for Hydraulic Use

1.Corrosion – Resistant in Hydraulic Fluids

Hydraulic fluids can be corrosive. But with 18% chromium and 8% nickel, the 304 stainless steel base resists rust and corrosion. This keeps the bar in top shape and prevents fluid contamination, ensuring system performance.

304 Chrome Plated Stainless Steel Bar Package