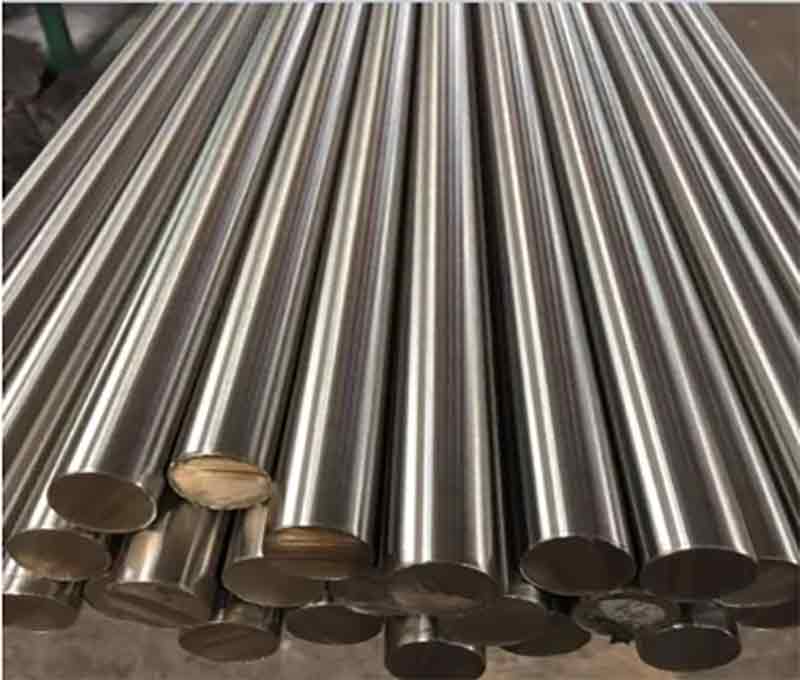

410 Stainless Steel Round Bar

410 Stainless Steel Round Bar

- Product Name: 410 Stainless Steel Round Bar

- Standards: Compliant with ASTM standards; equivalent to Chinese grade 1Cr13 (new national standard: 12Cr13).

- Chemical Composition: C≤0.15%, Si≤1.00%, Mn≤1.00%, P≤0.035%, S≤0.030%, Cr=11.50-13.50%, Ni≤0.60%.

- Dimensions: Available in outer diameters from φ3mm to φ800mm (customizable). Lengths can be tailored to customer requirements.

- Surface Finishes: Black skin, ground, polished, pickled, etc., to meet diverse needs.

- Origin & Manufacturer: Origin: China;

- Manufacturer: Wuxi Fengyu Machinery

- Price: prices vary by size, surface finish, and order quantity. Bulk discounts available.

Comparasion of Stainless 410, 420, 430 and 440

| Grade | C | Mn | Si | P | S | Cr | Ni |

|---|---|---|---|---|---|---|---|

| 410 | 0.15 max | 1.00 max | 1.00 max | 0.04 max | 0.03 max | min: 11.5 max: 13.5 | 0.50 max |

| 420 | 0.15 max | 1.00 max | 1.00 max | 0.04 max | 0.03 max | min: 12.0 max: 14.0 | – |

| 430 | 0.12 max | 1.00 max | 1.00 max | 0.040 max | 0.030 max | 16.0 – 18.0 | 0.75 max |

| 431

| 0.20 max | 1.00 max | 1.00 max | 0.040 max | 0.030 max | 15.00 – 17.00 | 1.25 – 2.50 |

| 440A

| 0.6 – 0.75 | 1.00 max | 1.00 max | 0.04 max | 0.030 max | 16.00 – 18.00 | – |

| 440B

| 0.6 – 0.75 | 1.00 max | 1.00 max | 0.04 max | 0.030 max | 16.00 – 18.00 | – |

| 440C

| 0.95 – 1.20 | 1.00 max | 1.00 max | 0.040 max | 0.030 max | 16.00 – 18.00 | – |

410 Stainless Steel Round bar Features

- High Strength & Hardness: Exhibits excellent strength and hardness, suitable for parts requiring resistance to heavy mechanical stress.

- Good Wear Resistance: Effectively resists mechanical and corrosive wear, extending service life in high-friction applications.

- Excellent Corrosion Resistance: This is the most prominent feature of 410 stainless steel round bar. Thanks to its high chromium content, a dense chromium oxide film is formed on the surface, which can effectively prevent the invasion of corrosive media. It has good resistance to corrosion in fresh water, steam, and air. It can also resist the erosion of most weak acids and alkalis, making it suitable for use in various humid and mild corrosive environments.

- Superior Machinability: Easy to cold processing (cold drawing, cold rolling, deep drawing, shearing) and can be welded, drilled, or stamped for further fabrication.

- Magnetic Property: A martensitic stainless steel with magnetic characteristics, ideal for applications requiring magnetism.

- Yield Strength: Up to 30 ksi

- Tensile Strength: Up to 65 ksi

- Elongation: Up to 20.0%

- Brinell Hardness: Up to 88

- Modulus of Elasticity: 20600 ksi

410 Stainless Steel Round Bar Packing & Shipping

- Mechanical Manufacturing: Shafts, gears, bolts, and other components requiring high strength and wear resistance.

- Automotive Industry: Engine parts, brake system components, enduring mechanical stress and environmental corrosion.

- Household Appliances: Knives, cutlery (spoons, forks), leveraging corrosion resistance and durability for daily use.

- Construction & Decoration: Railings, handrails, etc., with easy installation and resistance to outdoor corrosion.

- Nuclear Power: Structural components in nuclear power equipment, meeting stringent operational environment requirements.

410 Stainless Steel Round bar Processing Services

- Custom Samples: Small batch samples available based on customer drawings or specifications.

- Deep Processing: Stamping, bending, and other forming services to meet custom shape&size needs.

- Rough Machining: Cutting, slitting, and leveling to simplify subsequent processing for clients.

410 Stainless Steel Round Bar Packing & Shipping

- Packaging: Plywood case or cartons with protective padding to prevent damage during transit. Custom packaging available for special specifications.

- Shipping: Partnered with leading logistics providers. Options include express, road, rail, or sea freight, ensuring timely and secure delivery.