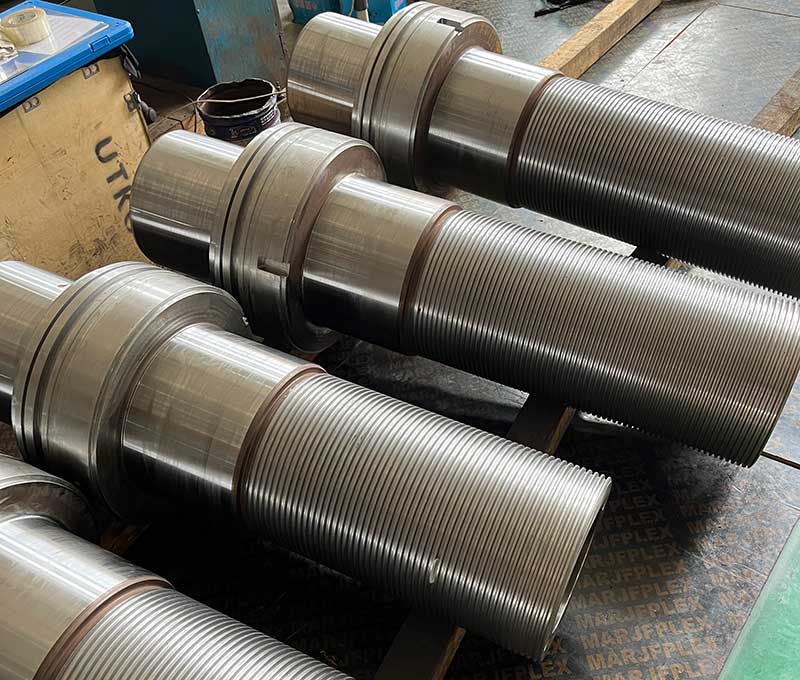

4140 Machining Chrome Rod

4140 Machining Chrome Rod/42CrMo Machined Rod

Material:Material:AISI4140/SAE4140/SCM440/42CrMo/42CrMo4

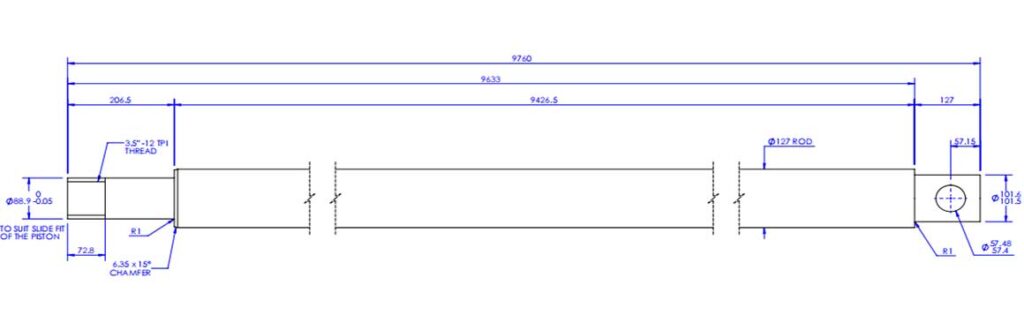

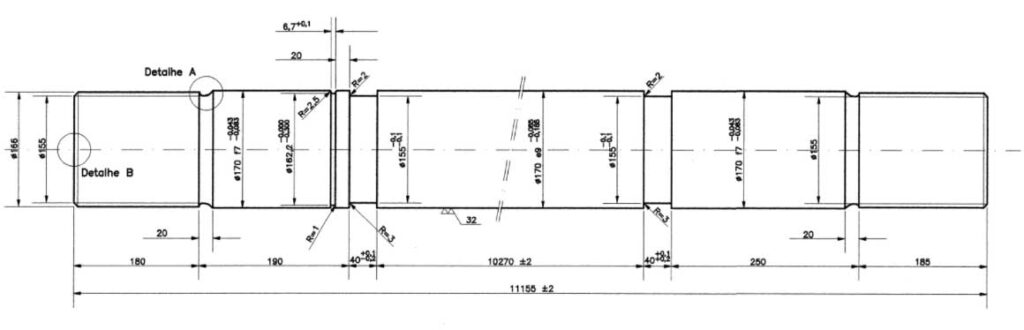

Machining Capabilities: Full Process Precision Manufacturing

- Machining Precision:

- Dimensional Tolerance: Outer diameter ±0.005mm, straightness ≤0.01mm/m, roundness ≤0.003mm (higher precision customization available).

- Surface Treatment: Roughness Ra≤0.2μm. Support hard chrome plating (thickness 20 – 150μm), induction hardening (hardness HRC45 – 55), and other processes.

- Equipment Strength:

- Imported CNC lathes (0.001mm level precision), grinding machines (Schleifring, Germany), and honing machines (Koyo, Japan) ensure full process machining.

- 100% inspection by coordinate measuring machines (CMM) and ultrasonic flaw detectors (UT) guarantees defect-free products.

4140 Machining Chrome Rod: High Strength, Precision, and Reliability

Item | Standard Value | Customizable Range |

Material | 4140 Alloy Structural Steel | 4130/4340/Stainless Steel |

Diameter Range | Φ10 – Φ200mm | Φ5 – Φ300mm (advance notice required) |

Length Range | 50 – 3000mm | Up to 5000mm |

Surface Treatment | Hard Chrome Plating/Black Oxide/Phosphating | Nickel – Phosphorus plating/Teflon coating |

Tolerance Grade | IT6 – IT7 | IT5 (precision grade) |

Applicable Industries | Construction Machinery/Hydraulic Equipment/Mining Machinery | Aerospace/Petrochemicals (special applications) |

4140 Machining Chrome Rod Chemical Properties, Mechanical Properties and Applications

| Performance Category | Specific Performance | Value |

|---|---|---|

| Chemical Composition | Carbon (C) | 0.38% – 0.43% |

| Silicon (Si) | 0.15% – 0.30% | |

| Manganese (Mn) | 0.75% – 1.0% | |

| Phosphorus (P) | ≤ 0.035% | |

| Sulfur (S) | ≤ 0.040% | |

| Chromium (Cr) | 0.80% – 1.10% | |

| Molybdenum (Mo) | 0.15% – 0.25% | |

| Iron (Fe) | Balance | |

| Physical Properties | Density | 7.85 g/cm³ |

| Melting Point | 1416℃ | |

| Mechanical Properties | Tensile Strength | 655 MPa |

| Yield Strength | 415 MPa | |

| Elastic Modulus | 190 – 210 GPa | |

| Poisson’s Ratio | 0.27 – 0.30 | |

| Elongation at Break (50mm Gauge Length) | 25.70% | |

| Brinell Hardness | 197 | |

| Knoop Hardness (Converted from Brinell Hardness) | 219 | |

| Rockwell Hardness B (Converted from Brinell Hardness) | 92 | |

| Rockwell Hardness C (Converted from Brinell Hardness) | 13 | |

| Vickers Hardness (Converted from Brinell Hardness) | 207 |

- Construction Machinery: Hydraulic piston rods for excavators and cranes, withstand high – load impacts.

- Industrial Equipment: Guide rods for injection molding machines and die – casting machines, support long – term high – frequency reciprocating motion.

- Special Scenarios: Anti – corrosion piston rods for marine engineering (nickel – phosphorus plating), tempered piston rods for high – temperature environments.

If there is demand for customized 4140 machining chrome rod, please feel free to contact: cassie@hydc-rod.com